How Much Does Custom Beef Cost?

An Outline of Pricing, Value, and Consumer Considerations

Introduction

High-quality beef is becoming a key focus for those interested in the food chain and their personal and family health. However, when many consumers look for higher quality products, they tend to be quickly discouraged by exorbitant prices.

This is not necessarily the case!

High-quality, locally produced beef often encourages transparency in sourcing, higher value, increased involvement, high customization, and reliable availability.

Supermarkets and common grocery stores tend to be more impersonal, but direct-to-consumer transactions cannot occur without YOUR input! You will know your producer, often have direct contact with the butcher, and be aware of intimate facts about your food.

Below, you will find the details about the various elements which determine the final cost you accrue as a consumer when buying custom beef, from the farm to the freezer or from pasture to plate.

After this article you will know key items to consider when searching, ordering, and receiving custom beef.

Define: Custom Beef

The purchase of whole, half, or quarter portions of a beef animal directly from a producer.

Direct-to-consumer relationships provide buyers with the opportunity to specify their product requests with details such as grass fed, grain finished, pasture-raised, organic, hormone-free, and the desired cuts, thickness of steaks, size of roasts, and other customizations, to include packaging specifications.

This process contrasts with buying pre-packaged steaks and roasts from a grocery store, where selections are more limited, cuts are more generic, and customization is not possible.

Factors That Determine the Cost of Custom Beef

Several key components affect the overall cost to the consumer purchasing custom beef:

Weight Pricing: The base price is often set per pound of the animal’s weight in various forms. The most common method is using the hanging, or rail, weight.

On-the-Hoof or Live Weight:

This method uses the weight of the animal shortly before or immediately prior to slaughter. This will have the lowest per pound price, but will also include head, hide, entrails, in addition to bone and meat. Live weight is the least predictable measurement of final packaged meat weight.

Hanging or Rail Weight:

This method uses weight after slaughter before further processing. This incorporates a hanging carcass with bone and meat only…think of the beef sides Rocky Balboa works out on in the movie Rocky.

Packaged Weight:

This method tends to be the most ‘expensive’ per pound but is only based on the meat that is packaged after the butcher processes and grill ready.

Processing Fees: After slaughter, the beef is processed by a butcher. This service typically incurs a fee, which may be charged per pound or at a flat rate or a combination of the two.

Flat fees are often slaughter and disposal fees.

Per pound feeds are typically the rail weight per pound cost, cut and wrap, or special packaging fees.

Cut and Wrap Charges: Additional costs beyond the base processing may be associated with specific cutting instructions and packaging.

Transportation Costs: Delivering the beef from the processor to the consumer or a pickup location can add to the total cost.

Storage Needs: Consumers need sufficient freezer space, possibly leading to a freezer purchase or rental costs.

Breakdown of Pricing Structures

1. Live Weight vs. Hanging Weight vs. Final Yield

Live Weight: The total weight of the animal before slaughter. Pricing on live weight is less common for consumers because it does not reflect the final meat yield as accurately.

Hanging Weight: Also called “rail weight” or "carcass weight," this is the weight after the animal is harvested, and once initial inedible parts are removed. Most custom beef pricing is based on this figure.

Final Yield (Packaged Weight): This refers to the actual weight of beef the consumer takes home, which is less than the hanging weight due to trimming, boning, and removal of excess fat or unnecessary bone.

For example, a steer with a live weight of 1,000 pounds may have a hanging weight of around 600 pounds, and a final yield of roughly 300 pounds of packaged meat. The difference between these weights is important for understanding how the initial per-pound price translates to what is received.

The easiest way to roughly calculate the weight is to take whatever the live weight is and multiply it by 30%. That will be your approximate cut-and-wrapped meat weight.

2. Average Per-Pound Pricing

Hanging Weight Price: Typically ranges from $3 to $6 per pound, depending on region, breed, and the producer’s reputation.

Processing Fee:

Commonly $0.90 to $1.50 per pound of hanging weight, or a flat fee ranging from $800 to $1,200 for a whole animal.

Some producers, like the Hashknife Ranch, receive a combination of fees for our 650 lbs. rail weight beef, which is budgeted and included in the rail weight pricing.

Customization Costs: Special requests, like specialty cuts, may have extra fees. Additionally, specialty packaging such as one steak per package, half pound burger packages, or pre-formed burger patties will result in extra costs.

After the inclusion of processing, or any additional costs and specialty requests, the final price per pound of take-home beef will average higher than the quoted hanging weight price.

What’s Included in the Cost?

Custom beef pricing generally covers:

The meat itself (in bulk: as whole, half, or quarter portions)

Butcher services: slaughter, processing, and packaging

Basic customization of cuts

Freezer storage costs, if applicable

Sometimes, delivery to a designated location

Some services may not be included and can be added to the total bill, so it is essential to clarify with both the producer and processor.

Additional Expenses to Consider

Apart from the direct purchase and processing fees, consumers should account for:

Freezer Space (to include purchasing a freezer): Purchasing a whole or half beef can yield hundreds of pounds of meat, necessitating significant freezer storage.

Upfront Payment: Most producers require a deposit at the time of order, with the balance due upon delivery or pickup.

Time Investment: Coordinating orders, specifying cuts, and arranging pickup or delivery require more involvement than supermarket shopping.

Shopping Decisions: You no longer need to think about the cuts you need to budget for each week. Instead, you grab whatever is available in your freezer, but that does not mean you will never return to the meat aisle for specialized cuts from time to time.

Our common example for store returns: Prime Rib roast may be a special in-store buy if you choose to make your roasts completely into rib steaks when completing your cut order.

Comparing Custom Beef to Retail Beef Prices

Custom beef often appears more expensive upfront, but the per-pound cost will almost certainly be lower than buying comparable cuts individually at a grocery store, especially for premium steaks and roasts. Additionally, consumers receive a variety of cuts, including ground beef, roasts, steaks, ribs, and sometimes organ meats—offering flexibility and value.

Remember, this single purchase will often feed a family between 12 and 18 months depending on the number of people and lifestyle requirements!

Example Cost Calculation

Suppose a consumer purchases a whole beef from the Hashknife Ranch with a rail weight of 635 pounds at our current price of $4.69 per pound:

Meat Cost: 635 lbs. x $4.69 = $2,931.25

Processing Fee (Average): $1,000

NOTE: For the Hashknife Ranch, we provide processing at no cost to the consumer because the ranch receives this bill and budgets for it with the $4.69 rail weight price.

Total Customer Cost = $2,931.25

If the final packaged yield is about 320 pounds, the effective cost is $2,931.25 ÷ 320 lbs. ≈ $9.16 per pound, including all the butcher cuts ranging from ground beef to high-end steaks.

This means you will clearly pay more for ground beef through custom orders than you will in the grocery store, but you will also pay drastically less for better quality, high-end steaks than you will in a retail store as well!

Real-World Example Cost with the Hashknife Ranch

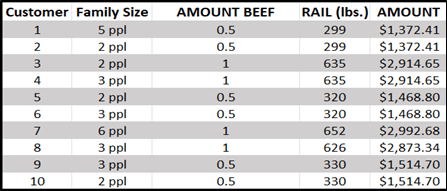

In 2024 the Hashknife Ranch, a family owned and operated ranch, sold customized direct-to-consumer beef to customers. Below is a small graph and a consolidated summary of the costs for our products for ten separate customers.

Our price was a set price of $4.59 per pound of rail weight. There was no processing fee, because we added that into our flat fee $4.59 cost. There was also no delivery fee for anyone within 100 miles, but some chose to pick up their products on their own.

Figure 1

After looking at the ten customer orders above, Figure 1, you will see below the consolidated averages in Figure 2, below.

Each carcass weighed approximately 640 pounds from an estimated 1,000-pound live-weight animal. The final packaged meat was half of the rail at about 320 pounds. Each pound of packaged meat resulted in about $9.20 per pound as the final tally.

Figure 2

Benefits of Paying for Custom Beef

Quality Assurance: Consumers can choose grass-fed, or grain-finished beef according to preference.

Customization: Unique cuts, thicknesses, and packaging to suit household needs.

Transparency: Clear knowledge of sourcing, animal welfare, production practices, butcher facility cleanliness.

Bulk Savings: Larger initial expenditure, but long-term savings compared to piece-meal retail purchases.

Supporting Local Producers: Direct transactions often support small, local farmers and ranchers while also impacting local businesses.

Potential Drawbacks

Large Upfront Cost: The initial investment can be significant, especially for whole or half animals.

Storage Requirements: Not practical for those without adequate freezer space.

Variety of Cuts: Some consumers may not want or know how to prepare fewer familiar cuts. For example, ordering medallion steaks cut from the tenderloin!

Wait Time (Planning): Custom beef may not be available instantly, as it often requires ordering months in advance.

Tips for Prospective Buyers

Research Producers: Look for reputable ranchers and processors with positive reviews and clear communication. Reach out to them and ask for time to have an honest conversation. Additionally, many have found word-of-mouth is the best indicator to true overall quality.

Clarify All Costs: Request a detailed breakdown of all possible fees before committing.

Share with Others: Consider splitting a whole or half beef with friends or family to lower individual costs and storage needs.

Plan Storage: Ensure you have enough freezer space before your beef is ready for pickup or delivery.

Understand the Process: Familiarize yourself with common cuts and cooking methods to take full advantage of the variety offered.

Ask the producer or processer for assistance in customizations that fits what works the most optimally for you and your family.

Conclusion

Paying for custom beef is a rewarding experience for many, offering quality, value, and a connection to food sources that retail purchases cannot always provide. However, it comes with unique costs and logistical considerations.

Understanding these elements helps consumers make informed decisions, ensuring that the investment in custom beef is both satisfying and cost-effective for their household.